A 150L distillation equipment setup typically represents a smaller-scale distillery system used by craft distilleries or hobbyists interested in producing limited quantities of spirits. This setup allows for a more intimate and hands-on approach to distillation.

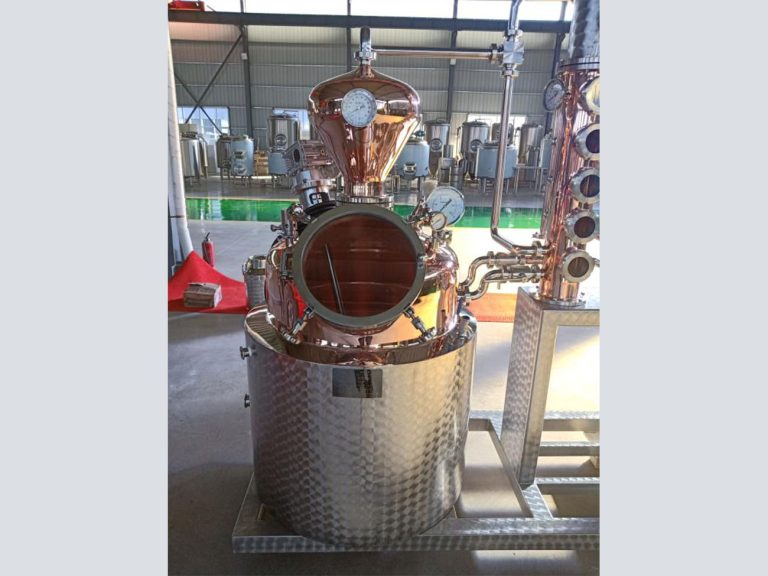

150L Distillation Equipment

A 150L distillation equipment setup typically represents a smaller-scale distillery system used by craft distilleries or hobbyists interested in producing limited quantities of spirits. This setup allows for a more intimate and hands-on approach to distillation.

Components commonly found in a 150L distillation setup might include:

Pot Still or Column Still: The main apparatus for distillation. Pot stills are often used for producing flavorful spirits like whiskey, while column stills are known for efficiency in producing neutral spirits such as vodka or gin.

Boiler or Mash Tun: Used to heat the mash or wash before distillation, preparing it for the distillation process by releasing alcohol vapors.

Condenser: Converts alcohol vapors back into liquid form by cooling them down, an essential part of the distillation process.

Fermenters: Tanks used for fermenting grains, fruits, or other raw materials to produce the wash or mash that will be distilled.

Storage Tanks: Utilized for storing distilled spirits before further processing, bottling, or aging.

Control System: Some setups may include basic control mechanisms to monitor temperatures and manage the distillation process.

Pumps, Valves, and Piping: Essential for transferring liquids between vessels and controlling material flow during distillation.

The 150L distillation equipment setup is well-suited for small-scale production, allowing for experimentation with recipes, smaller batch sizes, and greater hands-on control over the distillation process. It’s often favored by craft distilleries, boutique producers, or hobbyists who aim for artisanal spirits with a personalized touch.