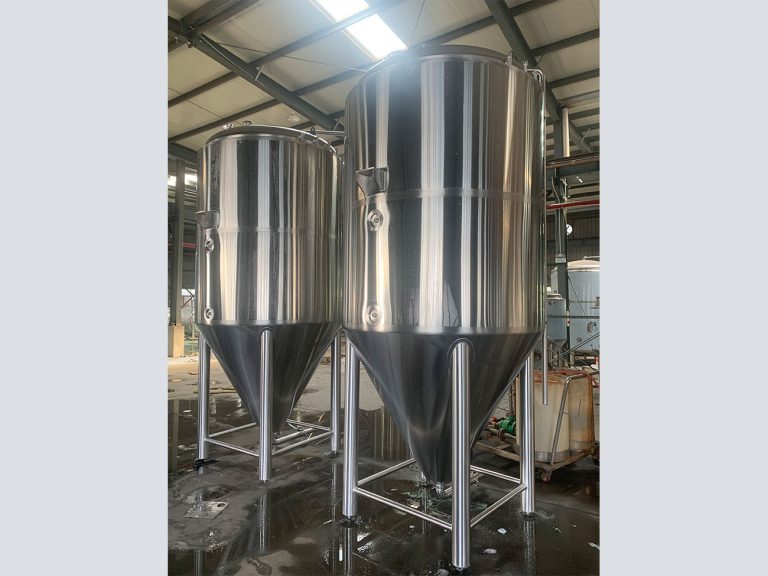

A 2000-liter (L) beer fermentation vessel is a sizable vessel used in breweries for fermenting and conditioning beer. These fermentation vessel are commonly found in medium to large breweries where substantial quantities of beer are produced.A 2000L fermentation vessel has a total capacity of 2000 liters, which is approximately 528 gallons. This capacity allows breweries to ferment significant volumes of beer in a single vessel, making it suitable for medium to large-scale production.

A 2000-liter (L) beer fermentation vessel is a sizable vessel used in breweries for fermenting and conditioning beer. These fermentation vessel are commonly found in medium to large breweries where substantial quantities of beer are produced.A 2000L fermentation vessel has a total capacity of 2000 liters, which is approximately 528 gallons. This capacity allows breweries to ferment significant volumes of beer in a single vessel, making it suitable for medium to large-scale production.

Advantage:

Certified stainless-steel material. Sanitary construction with 100% TIG welded joints and seams with sanitary interior polish. All fermentation vessel and jackets inspected and pressure tested to 2 times operating pressure. All fermentation vessel insulated with high efficiency polyurethane foam. We can custom fabricate any fermentation vessel to meet your brewery’s space and height restrictions. Fermentation vessel design pressure is 30 PSI。