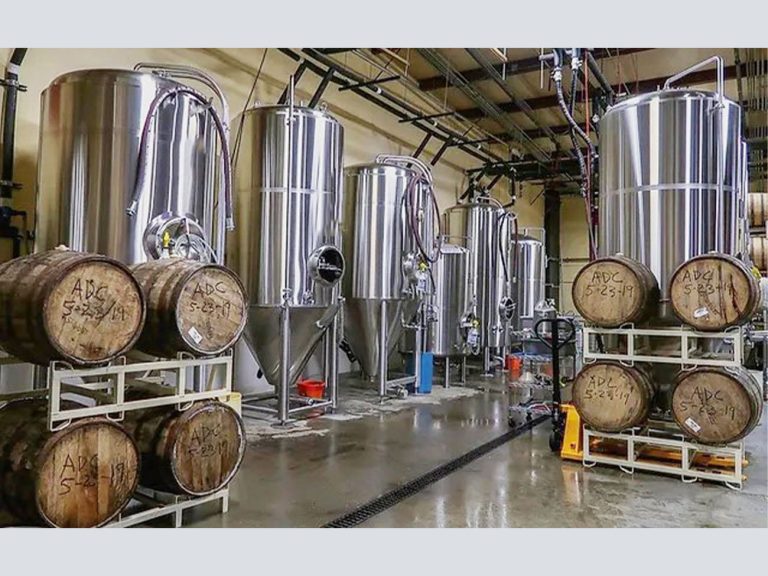

500L beer fermentation tanks and cellar control panel and CIP unit system were produced for Sweden. The customer purchased our 500L beer fermentation tanks in order to expand production, we have already arranged the shipping to our customer.

1.The specification for our 500L beer fermentation tanks as follows:

1).Effective capacity: 5hl; total volume: 750L;

2).External dimension:1060mmx2190mm;

3).Side manway;

4).Stainless steel 304;

5).Dome top head, cone bottom;

6).Surface brushed, welding line polish sanding light belt;

7).Polyurethane insulation, thickness: 80mm; inner body thickness 3mm, cladding thickness 2mm;

8).Double dimple plate cooling jackets, on wall and cone;

9).Working pressure is 2bar and testing pressure is 3bar;

10).With rotary CIP spray balls and arm;

11).PT100 temperature sensor;

12).4’’Dry hopping port on top head;

13).Sample valve in the cylinder;

14).Separate outlets for yeast and clear beer, beer racking arm located in the conical part of the tank

15).2’’PVRV;

16).Spunding valve;

17).Pressure gauge;

18).1.5’’ carbonation stone device;

19).2 ladder hooks;

20).Stainless steel legs with screw assembly to adjust leg height.

2.The cellar control panel is an integral part of the brewery as it helps regulate temperatures for cellar tanks to achieve the best fermentation and conditioning results, and The specification for Cellars Control panel system for beer unitanks as follows:

1).Stainless steel 304;

2).Display degree together;

3).The control panel with the on/off buttons, manual button control;

4).Beer fermentation tanks and bright beer tanks temperature control;

5). Pumps control;

6).With CE certification.

3.Also with one set 50L CIP unit system, including one sterilize tank, one alkali tank(with electric heating elements), CIP trolley, washing pump and control panel.

One month later our customer will be receive the tanks very soon, we do the beer fermentation tanks and others very carefully, and testing again and again at our factory, we are believe that they will very happy for our quality!